Bespoke Solutions

Bespoke Lighting Solutions for Controlled Environments

At Solite, we specialise in crafting custom lighting solutions tailored to your specific needs. With years of expertise, our skilled engineers can design and manufacture luminaires to fit existing apertures, new ceiling systems, or entirely new concepts. Whether your project is small, or large-scale, our team will work closely with you to deliver the perfect lighting solution.

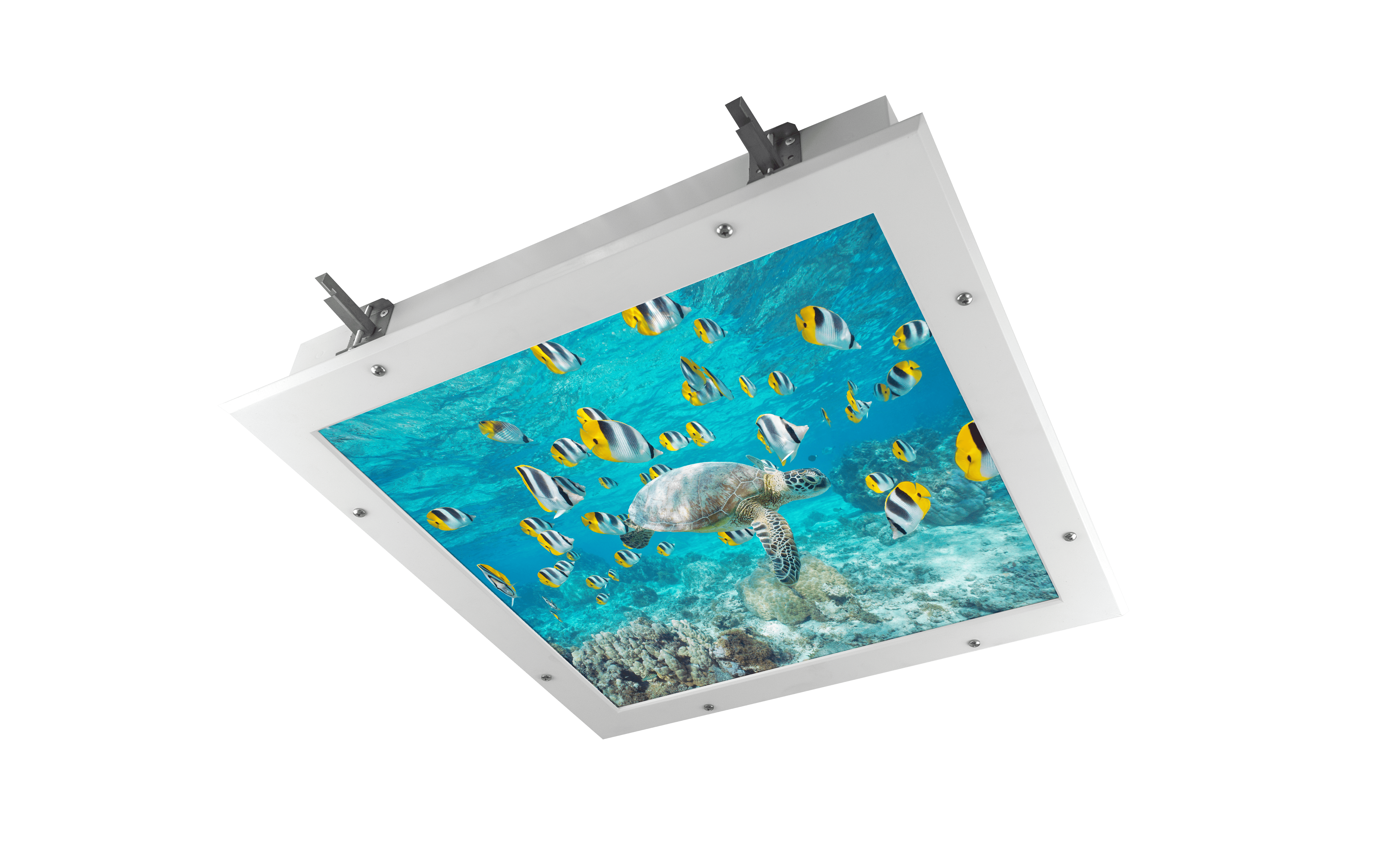

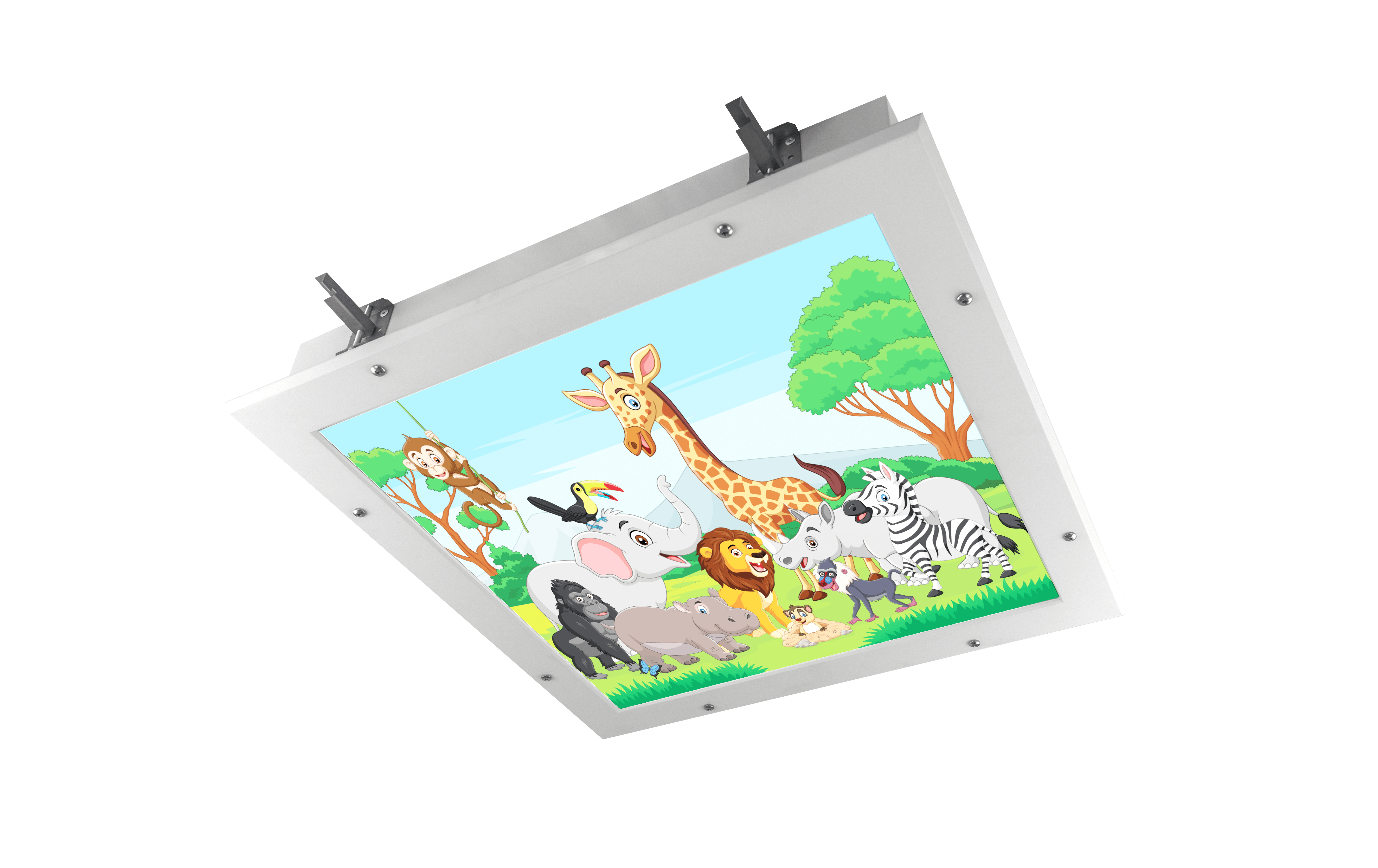

Visual interest lighting units

Solite was recently tasked with designing visually engaging lighting for a children’s ward at Russell Hall Hospital, to create a more welcoming and comfortable environment for patients and their families. Two bespoke designs were selected to transform the ward, ensuring it felt less clinical and more inviting. To achieve this, the luminaires were custom-built as 1200x1200mm units—a size rarely seen in the lighting industry. Rising to the challenge, Solite adapted its TAU range of luminaires to perfectly meet these unique requirements, utilising in house design and manufacturing, as well as screen printing on the inside of the polycarbonate diffuser to create these unique luminaires.

The TAU, an IP65-rated front and IP54-rated rear luminaire, is specifically designed to fit into both exposed T-grid and cut aperture ceilings. Its versatility and reliability make it a popular choice in healthcare settings, making it the ideal solution for this project.

please speak to the office on 0161 320 9999 for a bespoke solution or E-mail your request to: enquiry@solite-europe.com

Find out more

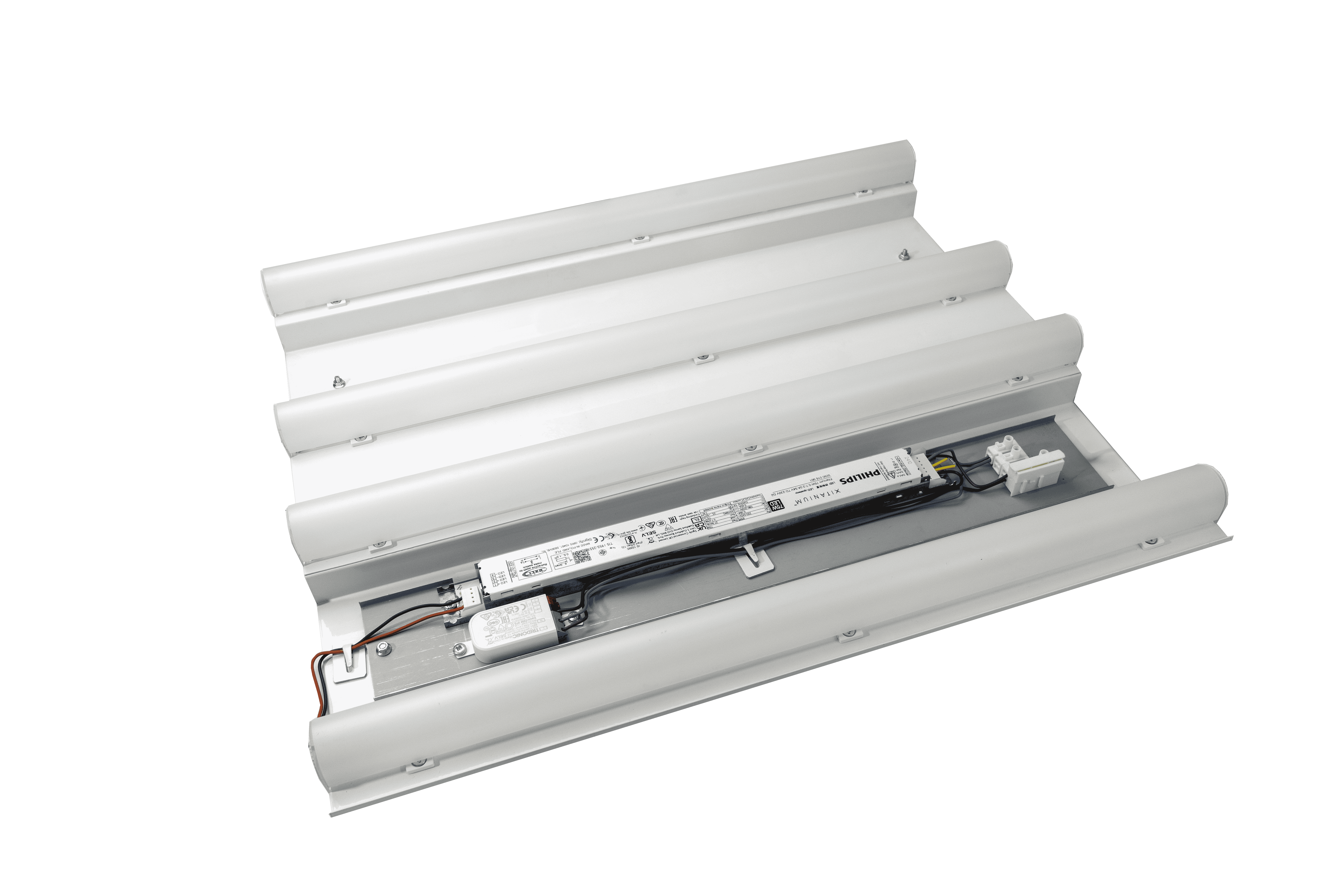

Retrofit Solutions - reduce, reuse & recycle

Solite Europe Ltd offers a comprehensive retrofitting service to old and degrading luminaires, whether they be fluorescent or older LED, Solite can offer a solution to the latest energy-saving standards. With extensive experience in retrofit and custom lighting solutions, Solite Europe combines flexibility, expertise, and advanced in-house manufacturing capabilities. This enables Solite’s engineers to deliver lighting solutions that carefully balance environmental, aesthetic, and economic factors, ensuring efficient, attractive, and sustainable results.

Why Retrofit Lighting with Solite Europe Ltd

As sustainability and circularity gain momentum, retrofitting has become an optimal way to modernise outdated lighting systems. Not only does it extend the lifecycle of existing luminaire housings, but it is also a cost-effective strategy to upgrade lighting efficiency.

By retrofitting with energy-saving LEDs, companies can reduce greenhouse gas emissions while improving lighting quality, comfort, and visibility. Additionally, LED retrofits offer benefits such as reduced maintenance, extended lifespan, and enhanced durability. Integrating intelligent lighting controls further optimizes energy use, driving down both consumption and costs.

Benefits of Retrofitting Lighting Systems

Opting for a retrofit lighting solution delivers a range of advantages, from economic savings and lower environmental impact to enhanced lighting performance. Solite Europe Ltd specialises in providing comprehensive retrofitting services, transforming non-LED fixtures or older LED systems to the latest high-efficiency technology. With a legacy in custom lighting solutions, Solite combines flexibility, in-house manufacturing, and engineering expertise to create solutions that align environmental, aesthetic, and financial considerations.

Preserving the Best of Both Worlds

Clients often wish to maintain the integrity of their existing infrastructure whilst upgrading as quickly as they can. Solite can meet this demand by re-engineering outdated components to retain the original luminaire housing, while updating its technology. Where needed, Solite can even produce bespoke LED circuit boards tailored to specific requirements, such as a change of us.

For any retrofit project, adequate light levels and uniformity are essential. Solite designs retrofits to match point-for-point replacement schemes or other spatial limitations, ensuring optimal lighting performance despite the challenges of older layouts. With modern LED and optical technology, Solite delivers significant improvements in lighting quality while preserving the original lighting setup.

Seamlessly Blending Tradition with Innovation

Adding Solite’s SmartScan controls to retrofitted luminaires, elevates energy efficiency by enabling wireless communication—ideal for retrofits as it requires no additional wiring. To retain the style and form of original fixtures, SmartScan Radar sensors use integrated high-frequency sensors for presence detection, offering energy savings without altering the luminaire’s physical structure.

The Retrofitting Process

Solite’s retrofit projects begin with a detailed site survey, assessing current luminaire types, locations, emergency signage, natural light sources, and existing controls. This allows precise energy calculations and design requirements. Engineers use samples or in-situ measurements to develop retrofit LED gear trays and components, ensuring perfect integration of old and new elements.

Once the solution is approved, Solite manufactures the retrofit kits and required mounting hardware at its UK facility, offering unmatched flexibility for projects of any size. With its full-service approach, Solite also provides turnkey installation and project management, ensuring seamless execution from start to finish.

By choosing Solite for your retrofit needs, you gain the benefits of improved energy efficiency, extended luminaire life, and expertly tailored lighting solutions—all crafted to elevate and modernise your space while honouring or improving its original specification.

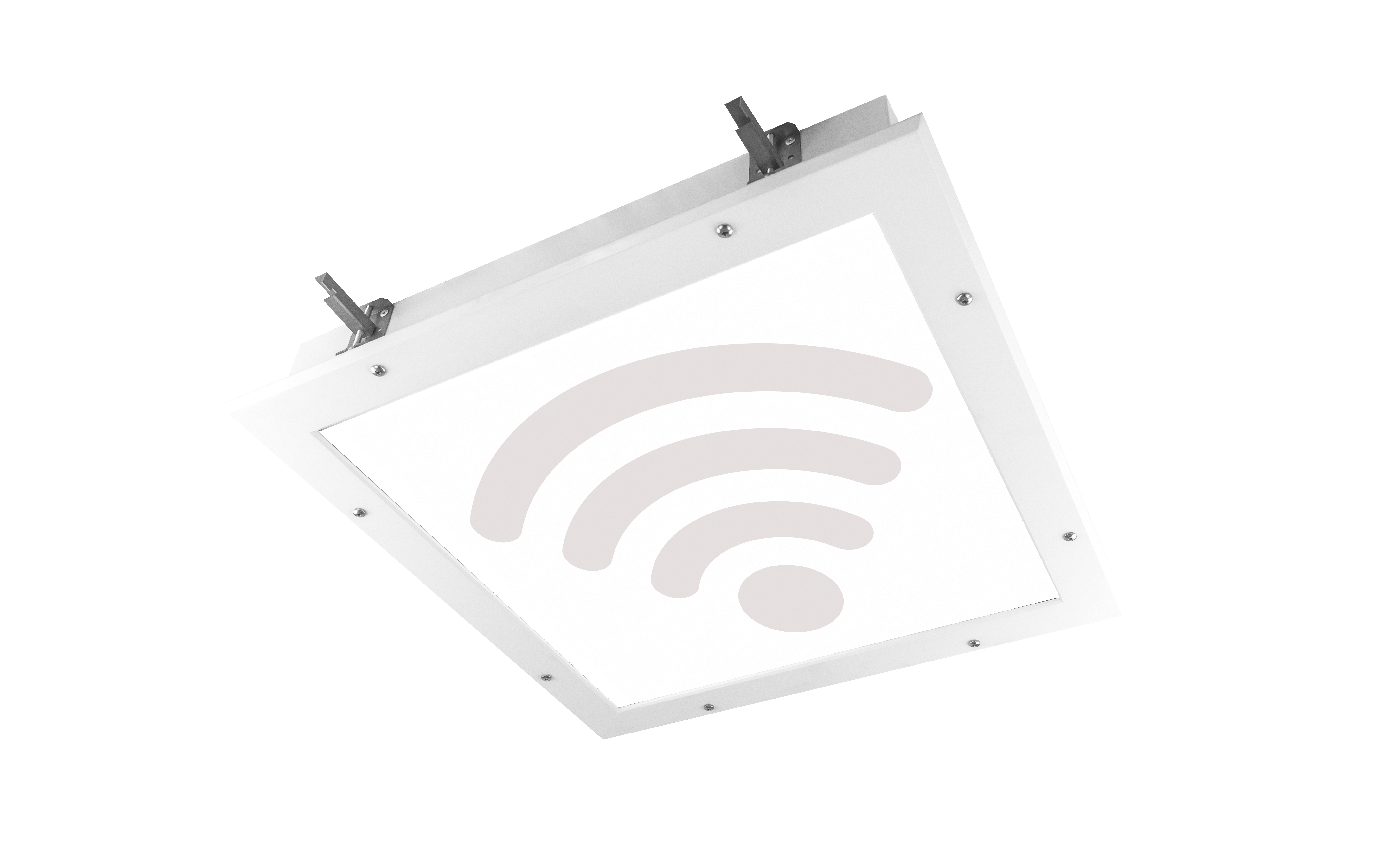

WAP Units

Wireless Access Points without breaking the integrity of your cleanroom

Full cleanroom grade Wireless Access Point (WAP) enclosures for both recessed and surface applications.

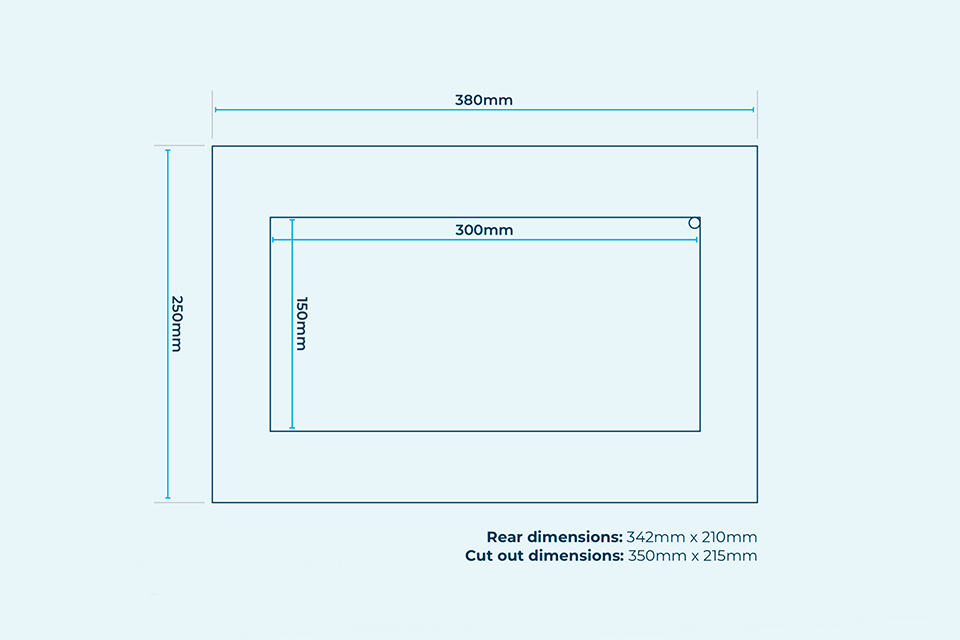

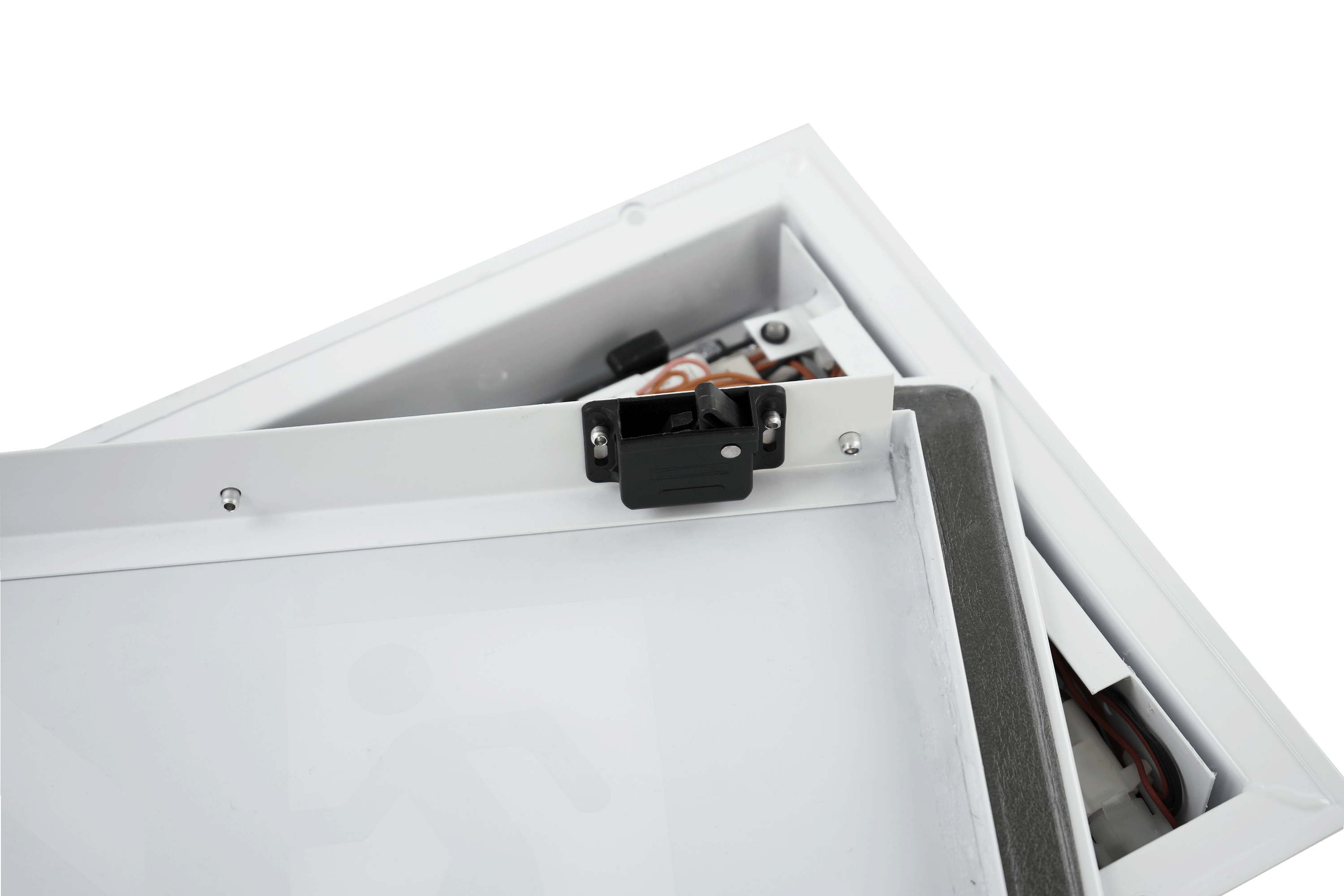

Recessed Version

- Class 6

- IP65 Front, IP54 Rear

- Walk on, T Grid, Spring T* and Cut Aperture

- Walk on variant can be made front or rear accessible

*Compatible with most Spring T ceilings, please check specific model prior to ordering.

Surface Version

- Class 5

- IP65

Units designed to fit WAP units, but can be used for other devices, please speak to the office on 0161 320 9999 for a bespoke solution or E-mail your request to: enquiry@solite-europe.com

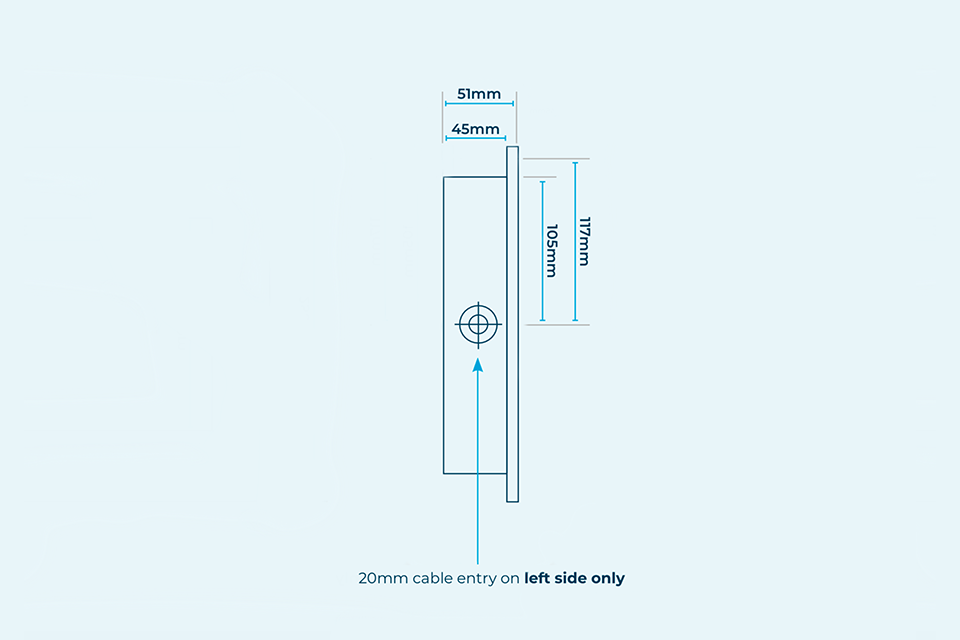

Cleanroom Recessed Exit Sign

Recessed cleanroom exit sign

Our client wanted a recessed exit sign, for cleanroom specific application that could be recessed into cleanroom wall panels, once installed a bead of mastic is applied leaving no discernible edge, therefore eliminating any build up areas that can commonly be a problem with recessed emergency lighting.

- IP65 from the front

- Screwless Front frame

- 45mm recessed depth and 51mm in total

- ISO7010 Screen printed legends

- White or Stainless Steel frame

This project was such a success, that Solite chose to launch the Recessed Exit sign, under the Solex name and it now sits proudly within our range.

Download

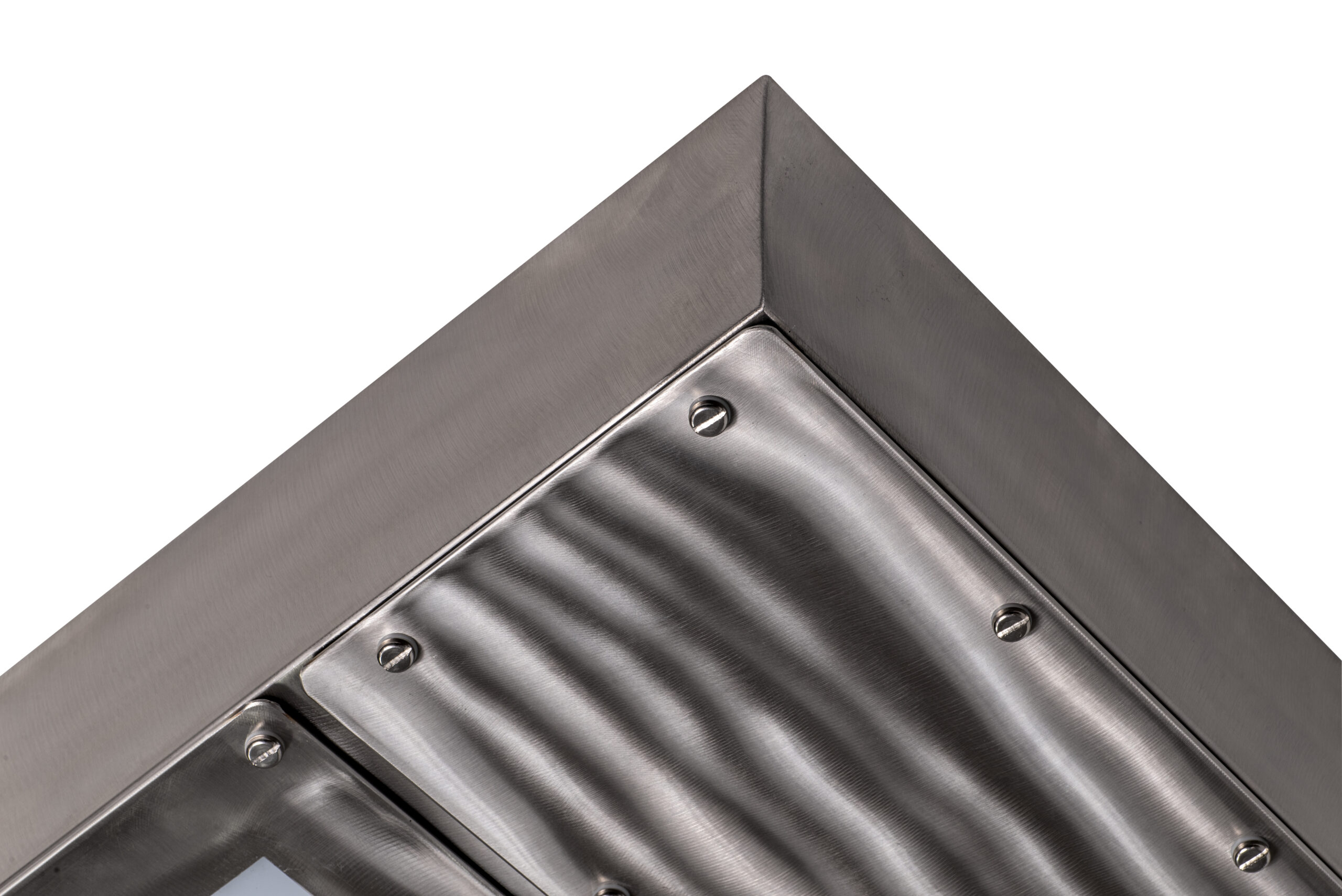

Stainless Steel surface mount

Stainless Steel Luminaire for Animal Welfare

Our client needed a luminaire for an animal welfare setting, designed with surgical-grade stainless steel and featuring circadian rhythm colour-tuneable LEDs. The unit includes:

- An inspection hatch for a 120mm Hawke transit ceiling penetration gland

- A full one-piece rear gasket with a 2mm silicone mastic channel for a complete seal to the concrete ceiling

- An IP65 body for robust protection

Additionally, the luminaire needed to be cleaned on a very regular basis, so oversized screws and retaining washers ensure the luminaire can be easily stripped and cleaned while wearing PPE, such as gloves safely and efficiently.

What we now call the Kappa SS was, designed, punched, folded, welded and assembled all in house, in our factory in Stockport, the level of finishing can be seen on the photographs and speaks volumes for the quality of our product.

Want to know more ?

To find out more about any of our products or services please contact us for further information.